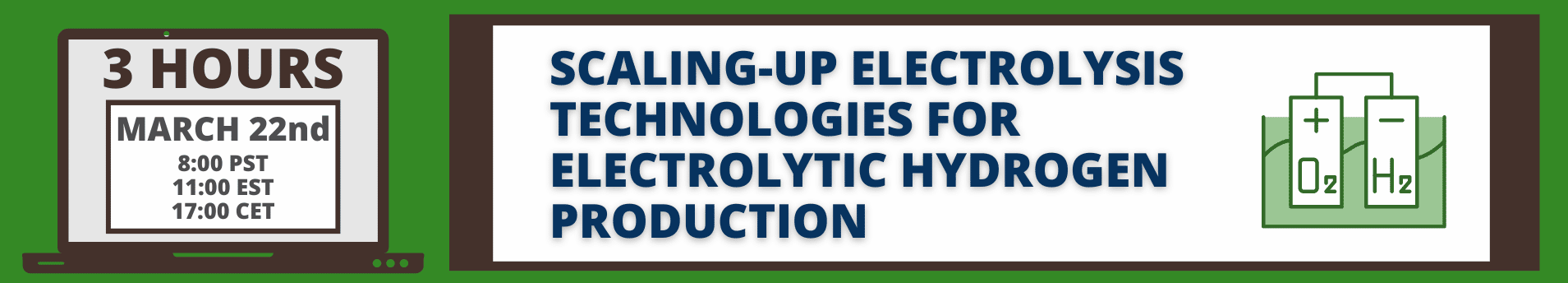

Workshop: Scaling-up Electrolysis Technologies for Electrolytic Hydrogen Production

Confirmed speakers:

Rangachary Mukundan

Senior Scientist, Lawrence Berkeley National Laboratory

Sergio Perez

Chemical Engineer

Pablo Ralon

Programme Officer – Renewable Energy Cost Status and Outlook

Ignacio Bincaz

Head of North America at H2Pro

Rohit Prasad

Sales Manager

David Wick

North America Sales Manager

David Bow

Executive Vice President

Marco Carrascosa

CEO

Nora Castañeda

Hydrogen Business Manager

Omar Rubio

NEB Business Development & Marketing Manager

Rasool Aghatehrani

Chief Marketing & Strategy Officer

Peter Marrin

Senior research analyst

Pedro Raposo

Director Power-to-X

Shalini Ramanathan

Director

Workshop's Agenda

Electrolyzer manufacturing needs to ramp up fast to support the global renewable hydrogen build up. Right now, there are just not enough electrolyzers to reach H2 production targets, but leading manufacturers have big expansion plans. Can electrolyzer manufacturing expand fast enough? Join this session to find out!

- Understand whether electrolyzer prices are heading south thanks to economies of scale or due to increase because of supply chain constraints and commodity prices

- Find out which companies are expanding electrolyzer manufacturing capacity, when by and where they are located

- Identify potential bottlenecks in electrolyzer supply and how to avoid them

Established electrolysis technologies such as Alkaline and PEM have been around for decades and their performance has been proven in the chemical industry. But as deployment has been limited, there is much work in improving efficiency, increasing durability, and reducing the cost of producing clean hydrogen using electrolyzers.

- Understand the pros and cons of each electrolysis technology so you can pick the one that is best for your renewable hydrogen project

- Learn more about how each electrolysis technology deals with the variability of renewable energy, and the costs and performance implications

- Hear about manufacturing scalability and efforts to increase the durability reduce costs and improve efficiency of electrolyzers

The DoE as well as the European Horizon program are focusing research institutions and companies into commercialization of electrolysis technology including improving efficiency, increasing durability, and reducing the cost of producing clean hydrogen using electrolyzers. In this sessions we look at the R+D efforts in the electrolyzer space and its impact in the industry as a whole.

- Understand how the program objectives of reaching a cost of cost target of $1/kg H2 by 2030 (and interim target of $2/kg H2 by 2025) impact the industry as a whole

- What is in the pipeline? In this session we look into R+D efforts to lower cost, decrease cell and stack degradation processes, increase efficiency for convert electricity to hydrogen and reducing the capital cost of the electrolyzer unit and the balance of the system

- Hear about new concepts of electrolyzers, as well as photocatalysis and photoelctrocatalysis that eliminate electrolyzers altogether and produce hydrogen directly from renewable resources

- Find out more about upcoming technologies such as AEM, SOEC and PEC that could deliver lower costs and higher efficiencies

Like any new technology, electrolytic hydrogen coming from renewable and other sources must go though a de-risking process in order to guarantee bankability of the project. In this session we look at how to make electrolytic hydrogen projects bankable from supply chain management to wrapping the full project.

- Learn how to de-risk your project with equipment warranties, lifecycle and degradation assessment of your electrolyser and other key equipment

- Speed past your competitors wrapping up the financing of your electrolytic hydrogen projects quickly and efficiently with best practice tips from expert financers

- Plan strategically and manage your supply chain to avoid bottlenecks, minimize costs and avoid delays

June 7 at 9:00 PDT / 12:00 EDT / 18:00 CEST